In the intricate and dynamic world of the oil and gas industry, countless components work in harmony to extract, transport, and refine the valuable resources that power our modern world. Among these components, valves stand as unsung heroes, silently orchestrating the flow of fluids and gases to ensure the seamless operation of this vital sector. In this comprehensive overview, we delve into the pivotal role that valves play in the oil and gas industry, exploring their diverse types and applications that drive efficiency, safety, and reliability.

Types of Valves and Their Functions

Gate Valves: These valves are like the traffic signals of the oil and gas industry. Their primary function is to either allow or block the flow of fluids. Gate valves are used for applications that demand unrestricted flow when fully open and minimal flow resistance when fully closed.

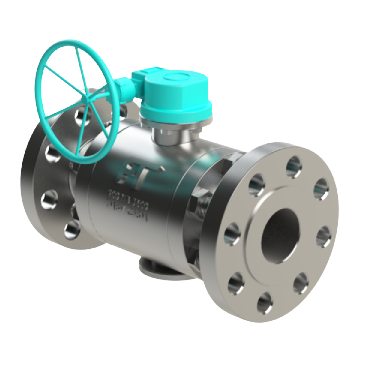

Ball Valves: Similar to gate valves, ball valves regulate fluid flow. However, they operate by using a spherical disc (the "ball") to control the flow path. Ball valves are known for their quick and reliable shutoff capabilities.

Check Valves: These valves work one way—permitting fluid flow in one direction while preventing backflow. They play a crucial role in preventing the reversal of flow in pipelines and protecting equipment from damage.

Globe Valves: Globe valves offer precise control over fluid flow. With a globe-like structure, they can be adjusted to regulate the flow rate accurately, making them suitable for applications that require fine-tuning.

Butterfly Valves: These valves are lightweight and cost-effective, with a circular disc that rotates to control flow. Butterfly valves find application in pipelines with large diameters and where quick shutoff is essential.

Applications of Valves in the Oil and Gas Industry

Upstream Exploration and Drilling: In the early stages of oil and gas extraction, valves are vital for controlling the flow of drilling fluids, preventing blowouts, and managing pressure during drilling operations.

Midstream Transportation: Valves are used to regulate the flow of crude oil and natural gas through pipelines. They ensure efficient transportation while minimizing leakage and environmental risks.

Refining and Processing: Refineries rely on valves for managing complex processes like fractionation, distillation, and chemical reactions. The precision of valve control directly impacts product quality and process efficiency.

Downstream Distribution: In distribution terminals and depots, valves manage the transfer of refined products to various transportation modes such as trucks, ships, and railcars.

Petrochemical Industry: Valves are integral to the petrochemical sector, facilitating the processing of raw materials into a wide range of chemicals, plastics, and other products.

As the backbone of the oil and gas industry, valves enable the movement of fluids and gases through the intricate network that powers our world. Their diverse types and applications showcase their adaptability to various oil and gas value chain stages. From upstream exploration to downstream distribution, valves contribute to efficiency, safety, and environmental responsibility. As technology advances, valves will play an increasingly integral role in optimizing operations, reducing risks, and ensuring the continued supply of energy resources. The oil and gas industry owes much of its success to these unassuming yet indispensable components—the valves that keep the flow steady.

.png)