In the realm of fluid control systems, selecting the appropriate valve is crucial for optimal performance and efficiency. Two popular choices that often stand out are Floating Ball Valves and Trunnion-Mounted Ball Valves. This blog aims to shed light on the key differences between these two valve types, empowering you to make an informed decision for your specific application.

Understanding the Basics:

Floating Ball Valves:

Floating ball valves derive their name from the way the ball is positioned within the valve. Unlike trunnion-mounted valves, the ball in a floating ball valve is not fixed in place. Instead, it moves slightly, allowing it to position itself against the downstream seat under the influence of fluid pressure. This design is particularly effective for low to moderate pressure applications.

|

| Floating Steel Ball Valve manufacturer |

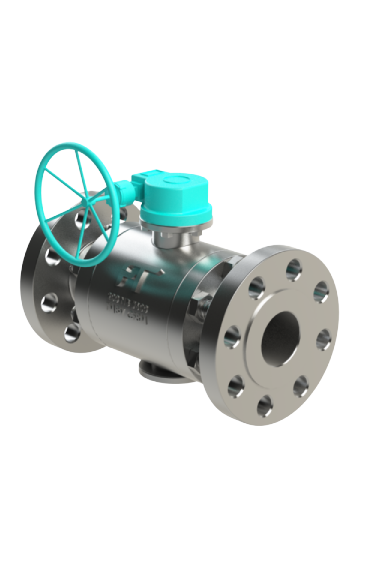

Trunnion-Mounted Ball Valves:

On the other hand, trunnion-mounted ball valves have a fixed ball, supported by a trunnion, or shaft, at both the top and bottom. This design is robust and well-suited for high-pressure applications. The trunnion ensures stability and reduces the load on the valve seats.

|

| Trunnion-Mounted Ball Valves |

Comparative Analysis:

Pressure Handling Capacity:

Floating Ball Valves: Ideal for low to moderate pressure systems.

Trunnion-Mounted Ball Valves: Excel in high-pressure applications.

Size Range:

Floating Ball Valves: Generally available in smaller sizes.

Trunnion-Mounted Ball Valves: Offer versatility in both small and large sizes.

Sealing Mechanism:

Floating Ball Valves: Rely on the force of the fluid to seal.

Trunnion-Mounted Ball Valves: Use trunnions to reduce operating torque and provide a more effective seal.

Applications:

Floating Ball Valves: Commonly found in industries with moderate pressure and temperature requirements.

Trunnion-Mounted Ball Valves: Suited for applications demanding high-pressure capabilities, such as oil and gas.

Choosing the Right Valve for Your Application:

The decision between a floating ball valve and a trunnion-mounted ball valve ultimately depends on the specific requirements of your system. Consider factors such as pressure levels, size constraints, and the nature of the fluid being controlled.

In the dynamic landscape of fluid control, making an informed choice between floating ball valves and trunnion-mounted ball valves is pivotal. Each design offers unique advantages, catering to different operational demands. By understanding the characteristics and applications of these valves, you can confidently select the one that aligns seamlessly with your system requirements.

No comments:

Post a Comment