Mumbai, the economic powerhouse of India, thrives on a complex network of industries – from petrochemicals and pharmaceuticals to power generation and food processing. Ensuring efficient flow control in these diverse operations is crucial, and that's where ball valves emerge as unsung heroes. Their simplicity, reliability, and versatility make them an indispensable component in countless industrial applications.

This comprehensive guide delves deep into the world of ball valves, catering to industry owners in Mumbai seeking the perfect fit for their unique needs. We'll explore:

Ball Valve Basics: Uncover the anatomy and different types of ball valves, along with their operating principles.

Material Matters: Understand how material selection impacts performance and suitability for various applications.

Mumbai's Manufacturing Muscle: Discover leading ball valve manufacturers in Mumbai, renowned for their expertise and quality.

A Buyer's Guide for Success: Equip yourself with crucial factors to consider when choosing the right ball valve for your industry.

Beyond the Basics: Explore advanced features and considerations for maximizing efficiency and safety.

Unmasking the Ball Valve: Anatomy and Function

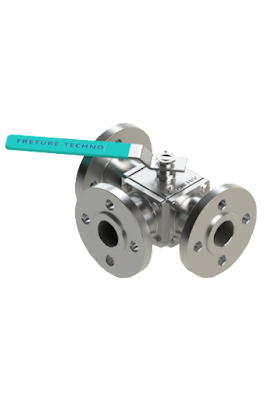

At their core, ball valves feature a perforated sphere (ball) housed within a cylindrical body. This ball, typically made of metal or high-performance plastic, rotates around a central stem to regulate flow – a quarter turn opens or closes the valve completely. This simple yet effective design grants several advantages:

Low maintenance: Compared to other valve types, ball valves require minimal maintenance due to their minimal moving parts.

Leakproof performance: Tight sealing around the ball minimizes leakage risks, ensuring safety and operational efficiency.

Fast operation: A quarter-turn operation allows for quick flow control, crucial in dynamic industrial processes.

Wide range of applications: Ball valves can handle diverse fluids, pressures, and temperatures, making them adaptable to various industry needs.

Material Matters: Choosing the Right Alloy for Your Flow

The material of your ball valve plays a critical role in its performance and compatibility with specific applications. Here's a breakdown of some commonly used materials and their strengths:

Stainless Steel: Durable, corrosion-resistant, and suitable for high temperatures and pressures – ideal for food processing, chemical plants, and power generation.

Brass: Affordable, corrosion-resistant, and suitable for lower pressures and temperatures – commonly used in plumbing and domestic applications.

Bronze: Strong, wear-resistant, and handles abrasive fluids well – used in oil and gas, mining, and marine applications.

High-Performance Polymers: Lightweight, corrosion-resistant, and ideal for handling corrosive fluids – frequently used in chemical and pharmaceutical industries.

Remember, material selection should be based on your specific industry, fluid type, pressure and temperature requirements, and budget. Consulting with a reputable ball valve manufacturer in Mumbai can ensure the optimal material choice for your needs.

A Buyer's Guide for Success: Choosing the Right Ball Valve

Selecting the ideal ball valve for your Mumbai-based industry requires careful consideration of several factors:

- Size and Pressure Rating: Choose a valve size that matches your pipe diameter and a pressure rating exceeding your maximum operating pressure.

- Material Compatibility: Ensure the valve material is compatible with the fluids you'll be handling, preventing corrosion or contamination.

- Port Configuration: Select the appropriate port configuration (threaded, flanged, etc.) to match your existing piping system.

- Actuation Type: Choose between manual, pneumatic, or electric actuation