The oil and gas industry is characterized by complex operations and the necessity for reliable equipment that can perform under extreme conditions. Within this context, These valves have been recognized as one of the most vital components. Their unique design and functionality render them indispensable in both upstream and downstream processes. This article will explore how these valves are utilized throughout the oil and gas sector, their advantages, and their impact on operational efficiency.

Understanding Ball Valves

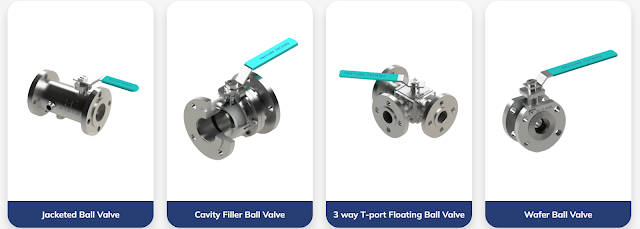

They are designed to control the flow of fluids in a pipeline. They are composed of a spherical disc—the ball—which regulates flow through an opening in the valve body. When the valve handle is turned, the ball rotates, allowing or blocking flow. Their robust construction and simple operation make them popular in the oil and gas industry, where durability and reliability are paramount.

Ball Valves in Upstream Processes

In upstream operations, which encompass exploration and production, They are employed extensively. Oil and gas exploration involves the drilling of wells, and during this critical phase, the control of fluid flow is essential. They are used in wellheads and separators. In wellheads, they facilitate the controlled release of hydrocarbons, ensuring that pressure is maintained and managed safely. This is crucial for safe drilling operations, as uncontrolled flow can lead to hazardous blowouts.

In separators, they play a key role in distinguishing between oil, gas, and water extracted from the well. By controlling the flow rates effectively, these valves help in optimizing the separation process, ensuring maximum yield and purity of extracted products. Furthermore, they are often paired with automation systems that enable remote monitoring and operation, enhancing safety and efficiency during extraction.

Ball Valves in Upstream Processes

After the extraction phase, the focus shifts to refining and distribution, known as downstream operations. Here, these valves continue to prove their value. In refineries, where crude oil is processed into usable products, these valves are utilized in various applications including fluid handling, chemical processing, and thermal regulation.

The refining process can involve harsh environments with varying temperatures and pressures. Built with materials that can resist these conditions, the valves ensure the smooth operation of refinery processes. Their tight sealing capability is particularly important in preventing leaks of volatile substances, thereby increasing safety and minimizing environmental impact.

Additionally, These valves facilitate the transport of refined products through pipelines. When transferring fuels, lubricants, and chemicals, the efficiency of flow control becomes essential. It can be opened and closed quickly, allowing for precise control over the amount of product being transported. This dynamic flow control is vital for maintaining system integrity and operational efficiency.

Advantages

Several advantages contribute to the popularity of these valves in the oil and gas industry. One of the foremost benefits is their high durability. They are constructed to withstand extreme conditions, including high pressures, corrosive materials, and varying temperatures. This durability translates to longer service life and reduced maintenance costs

Another significant advantage is the reliability of Ball valves. Due to their simple design, they are less prone to failure compared to other valve types. This reliability is particularly important in the oil and gas sector, where the consequences of valve failure can lead to serious safety risks and financial losses.

Moreover, these valves provide quick operation. With a quarter-turn mechanism, they can be activated swiftly, enabling rapid response to changing flow conditions. This feature is especially beneficial in emergency situations where immediate action is required to contain leaks or prevent accidents.

Innovations and Future Outlook

As the oil and gas industry continues to evolve, so do the technologies surrounding Ball valves. Recent innovations have focused on developing smarter, more efficient valves that cater to modern industry demands. For instance, advancements in materials science have led to the creation of corrosion-resistant coatings, enhancing the longevity of these valves in even the harshest environments.

Moreover, the integration of digital technologies has transformed the valve operation. Smart Ball valves equipped with sensors now allow for real-time data monitoring and remote operation capabilities. This provides operators with insights into valve performance, enabling predictive maintenance and reducing downtime.

The future of Ball valves in the oil and gas industry appears promising, with ongoing research and development aimed at enhancing their functionality. As the push for more sustainable practices increases, innovations focusing on energy efficiency and reduced environmental impact are prioritized.

In summary, the critical role of Ball valves in the oil and gas industry cannot be overstated. Their versatility and reliability make them essential in both upstream and downstream processes, directly contributing to operational efficiency and safety. With ongoing advancements in technology, the effectiveness of Ball valves is expected to improve further, reinforcing their position as a cornerstone of the oil and gas sector. As industries continue to seek safer and more efficient operations, Thel valves will remain a fundamental element of petroleum engineering, ensuring that the energy demands of the future are met sustainably and reliably.

.png)