In the high-demand environments of chemical and fertiliser manufacturing, process engineers continuously seek compact, efficient, and durable flow control solutions. One such device that is rapidly gaining preference in these industries is the Wafer Type Ball Valve. Known for its space-saving design and tight shut-off capabilities, the wafer type ball valve is becoming a go-to choice for modern plant layouts where installation space is limited, but performance cannot be compromised.

As a mechanical engineer, I can confidently say that when selected and implemented correctly, wafer type ball valves offer a balanced mix of economy, reliability, and application-specific adaptability. Today, Indian manufacturers are emerging as strong suppliers of these valves, offering globally compliant designs suited for aggressive process environments.

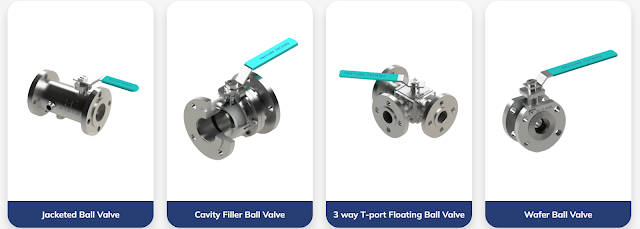

What is a Wafer Type Ball Valve?

A wafer type ball valve is a compact version of the traditional ball valve, designed to fit between two flanges using minimal space. Unlike flanged valves that are bulkier and require more bolt holes, wafer style valves are mounted directly between pipeline flanges—making them ideal for compact skid units and modular process equipment.

|

| Wafer Type flange Ball Valve |

The key features include:

-

Quarter-turn operation for fast opening and closing.

-

Short face-to-face dimension, reducing installation footprint.

-

Lightweight design, helpful in suspended or mobile piping systems.

-

Bubble-tight sealing, ensuring zero-leakage in critical chemical processes.

These characteristics make wafer type ball valves highly effective for both isolation and control duties in chemical dosing systems, fertiliser mixing units, and utility pipelines in plants.

Applications in Chemical and Fertiliser Industries

Chemical and fertiliser processes often involve:

-

Corrosive fluids (e.g., hydrochloric acid, sulfuric acid).

-

Volatile gases (e.g., ammonia).

-

Slurry or viscous materials.

-

High-pressure or high-temperature conditions.

Wafer type ball valves are particularly well-suited for:

-

Dosing and metering systems, where compactness and precision are required.

-

Skid-mounted units, commonly used in fertiliser formulation or blending lines.

-

Chemical transfer systems in tight spaces, such as between tank outlets and transfer pumps.

-

Cooling water and utility lines where regular maintenance access is needed.

Thanks to their low torque operation and modular construction, these valves are ideal for automation as well.

Material Selection for Harsh Process Media

In chemical and fertiliser plants, corrosion resistance is not optional—it’s essential. Indian valve manufacturers offer wafer type ball valves in a variety of materials to handle diverse applications:

-

Stainless Steel (SS 316/304) – For general chemical resistance and hygiene compliance.

-

PTFE / PFA Lined Valves – For highly corrosive environments; ideal for acids and solvents.

-

Hastelloy and Alloy 20 – For special chemical environments like nitric acid or mixed fertilizers.

-

Carbon Steel – With special coatings for non-corrosive utilities like cooling water or compressed air.

Internals such as seats and seals are often offered in PTFE, RPTFE, or PEEK, depending on temperature and media compatibility.

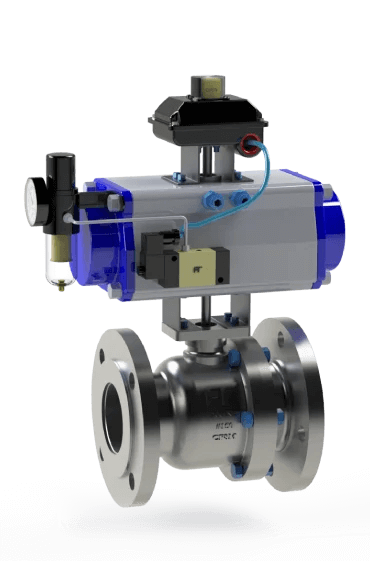

Automation and Operational Efficiency

To enhance safety and reduce manual operations, wafer type ball valves can be integrated with:

-

Pneumatic or electric actuators

-

Position indicators and limit switches

-

Fail-safe actuators for emergency shutdown systems

This allows seamless integration into automated control systems in both batch and continuous processing units. Indian manufacturers now provide pre-mounted valve-actuator assemblies that comply with ISO 5211 mounting standards, reducing commissioning time.

Standards and Quality Assurance

Wafer type ball valves from reputable Indian manufacturers are designed and tested to meet:

-

API 6D / API 608 standards for performance and durability.

-

ASME B16.34 for pressure-temperature ratings.

-

Fire-safe design (API 607) for hazardous chemical applications.

-

ISO 15848 for fugitive emission control.

Each valve undergoes hydrostatic testing, seat leakage testing, and in some cases, spark or conductivity testing for anti-static performance, especially important in volatile gas handling.

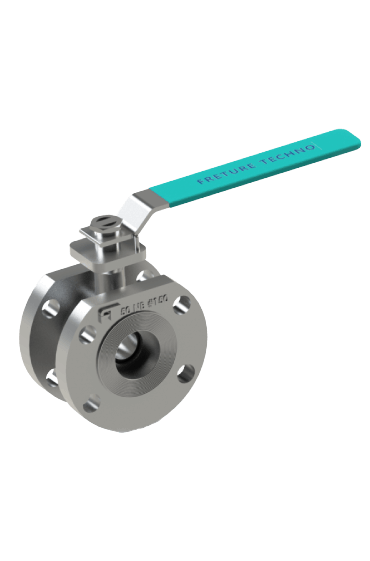

Leading Indian Manufacturer: Freture Techno Pvt. Ltd.

India has established itself as a competitive hub for industrial valve solutions, and Freture Techno Pvt. Ltd. is one of the names leading this charge. With expertise in manufacturing wafer type ball valves for critical applications in chemical and fertiliser plants, Freture offers products that meet international standards while being tailored to India’s industrial needs. Their valves are available in a range of body materials, seat options, and automation-ready configurations.

To conclude, Wafer Type Flange Ball valves offer a smart, compact, and high-performance solution for flow control in chemical and fertiliser facilities. With the right material selection, automation features, and adherence to international standards, these valves ensure both safety and efficiency. Indian manufacturers like Freture Techno Pvt. Ltd. continue to deliver innovation and reliability, supporting the growing demands of the process industry.